光束直徑對 LDT 的重要性

雷射資源指南第14.7。

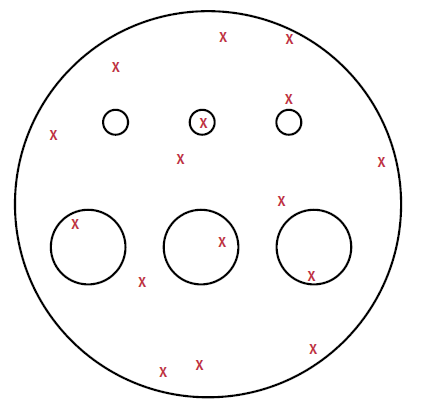

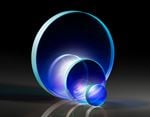

雷射直徑對光學元件 LDT 具有高度影響,因為光束直徑會直接影響 雷射誘發損傷 機率。1 用於 LDT 測試的雷射光束尺寸,若遠大於光學元件瑕疵密度,觸發罕見損傷機制的機率就相當高;前述罕見事件是可偵測的。如果光束太小,就不一定能夠偵測低密度瑕疵,造成高估零件承受損傷的能力 (圖 1)。

圖 1: 測試時小直徑光束比較不可能與光學元件的低密度瑕疵重疊,產生過度樂觀的 LDT 值

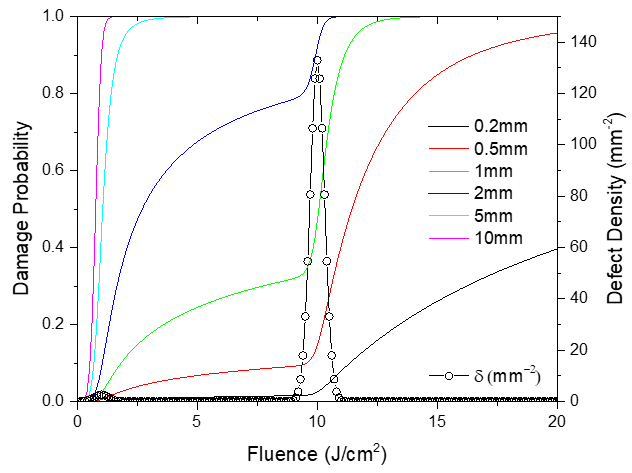

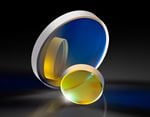

ISO 21254 之中規定 LDT 測試允許的最小光束直徑為 0.2mm。許多雷射光學元件供應商認為使用的光束越小越好,因為這樣比較容易達成高通量,但這種作法可能導致表面“取樣不足”。圖 2 顯示雷射損傷如何隨光束直徑調整。在其中顯示的情境中,有大量瑕疵具有 10J 的閾值通量,少數瑕疵具有 1J 的閾值通量。這項簡化模型提供見解說明真實使用情形,因為雷射光學元件通常包含各種類型瑕疵,密度各不相同,並具有個別損傷閾值。將光束直徑由 0.2mm 調整為 10mm,將大幅改變損傷機率函式,進而改變測試得出的 LDT 值結果。使用 0.2mm 光束時,偵測到其中一個 1J 閾值瑕疵的機率相當低。因此損傷機率將維持非常低的水準,直到達到 10J 通量。將光束大小由 0.2mm 增加至 2mm,能夠提升偵測 1J 閾值瑕疵的機率,進而造成 1J 通量的損傷機率急遽上升。光束直徑調整為 10mm 時,1J 的損傷機率將會增加,達到幾乎一定會發生損傷的程度。

圖 2: 在此具有 2種不同類型瑕疵的範例中,將光束尺寸由 0.2mm調整為 10mm 時,LDT 值降低 10 倍

雖然 LDT 會隨波長及脈衝期變化而調整,但也會隨光束直徑調整。如果是小幅度變化光束直徑,可利用下列方式約略估計此項調整:將原始 LDT 值乘以原始直徑與新直徑比例的平方。1

公式 1 approximates the shift of an LIDT at an initial wavelength (λ1), pulse duration (τ1), and beam diameter (∅1) to a new wavelength (λ2), pulse duration (τ2), and beam diameter (∅1). Our Laser Induced Damage Threshold Scaling Calculator provides approximations for scaling an LIDT value for small shifts in beam diameter and the other application conditions.

參考資料

- L. Gallais, J. Capoulade, J.-Y. Natoli and M. Commandré, "Investigation of nanodefect properties in optical coatings by coupling measured and simulated laser damage statistics," J. Appl. Phys, vol. 104, p. 053120, 2008.

上個章節

上個章節

or view regional numbers

QUOTE TOOL

enter stock numbers to begin

Copyright 2023, Edmund Optics Inc., 14F., No.83, Sec. 4, Wenxin Road, Beitun District , Taichung City 406, Taiwan (R.O.C.)

California Consumer Privacy Act (CCPA): Do Not Sell My Information